Press & Case Studies

Movetech UK response to the Government Announcing Longer Lorries on British Roads

In May 2023, following a trial of around 3,000 vehicles, the Government announced that from 31/05/23 the maximum length of articulated lorries on British Roads is increasing from 16.5m to 18.55m[1]. The Government sees the introduction of Longer Semi Trailers (LSTs) as an important, easy and affordable measure to continue to reduce CO2 emissions from the haulage industry without significant technological and infrastructure development. As the UK leading experts and manufacturers of vehicle access turntables, Movetech UK consider the implications of these new Longer Semi Trailers (LSTs) on truck turntables in new and existing developments.

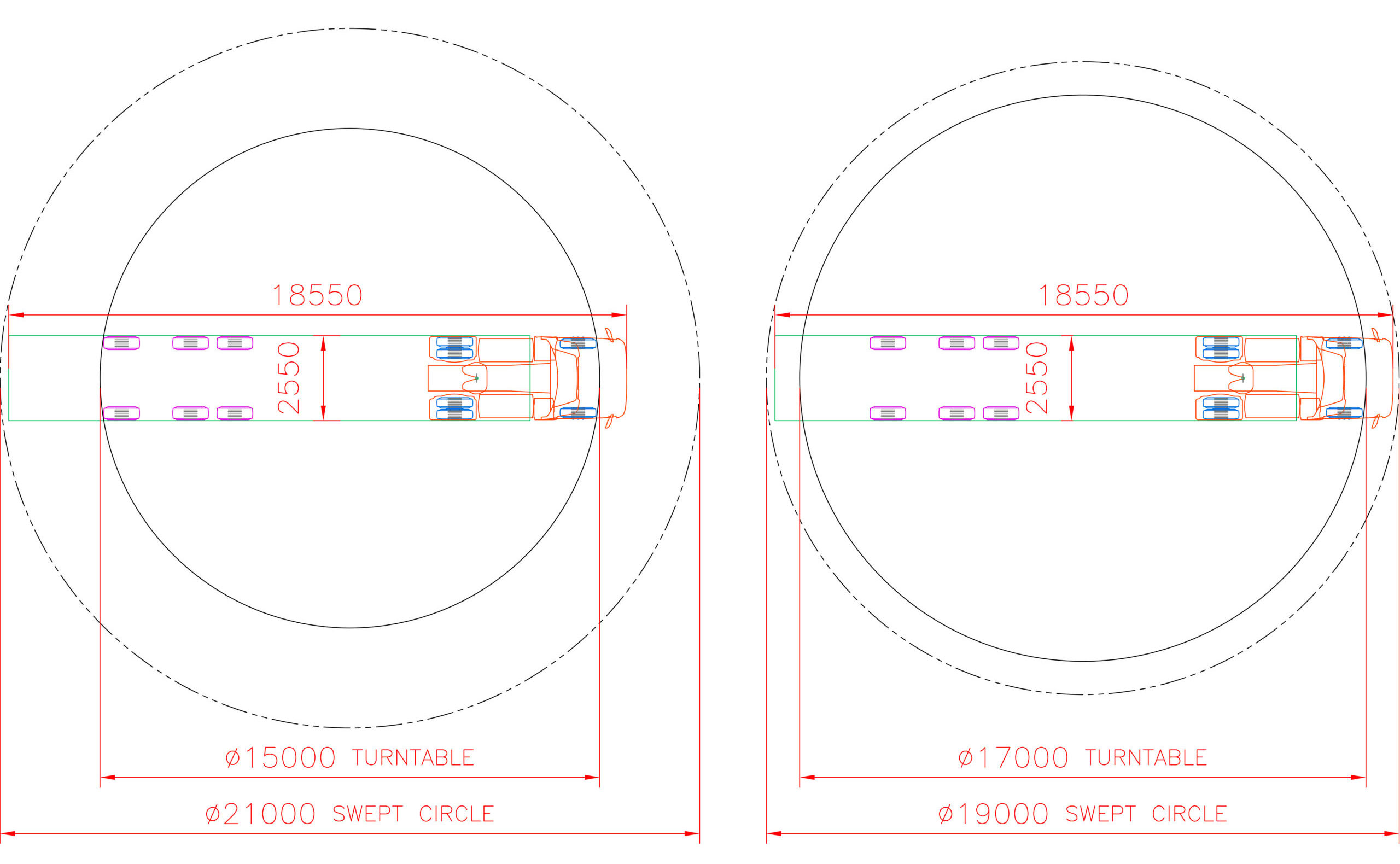

The most efficient turntable size for 16.5m trucks is Ø15m turntable with a Ø17m ‘swept circle’. The ‘swept circle’ being the area in which the lorry overhang rotates beyond the turntable. As the new maximum lorry length of 18.55m is already beyond the current swept circle diameter, the question for organisations with an existing turntable-equipped yards is: Will my existing turntable accommodate the Longer Semi Trailers?

The simple answer is probably not. Using the dimensions of Longer Semi Trailers from the Don-Bur website[2] it looks theoretically possible to get an 18.55m lorry on our Ø15m turntable, however vehicles would need to be parked extremely accurately with the front and rear wheels only just be on. However, with the significantly longer rear overhang of the LSTs this would mean a swept circle of just less than Ø21m. This space requirement will be outside the scope of the original method statement, therefore operators of existing turntable-equipped yards should contact Movetech UK to help assess whether they have the space to safely rotate 18.55m lorries on an existing Ø15m turntable.

For clients considering the most efficient use of space for new developments that wish to accommodate LSTs the question will be: What size of turntable do I need for the Longer Semi Trailers?

The smallest ‘swept circle’ in which we can comfortably rotate an 18.55m long truck is Ø19m. By keeping the turntable diameter down to Ø17m we can reduce the risk of the vehicle being parked off-centre by keeping the front wheels near the edge of the turntable, but still allow for a margin of error from the driver when positioning the truck. Our standard Ø17m turntable used for road trains, or wagon-and-drag, is perfect for this new longer articulated lorry.

In conclusion, the 2.05m increase in maximum vehicle length for articulated vehicles will likely mean that operators of existing Ø15m turntables will have to specify that they can only accommodate 16.5m vehicles. Meanwhile developers of new facilities that wish to accommodate LSTs will require 25% more area in the yard to rotate these longer vehicles than they would if they limited vehicle length to 16.5m.

QT0360-1 HGV Turntable Options With LST:

References:

[1] https://www.gov.uk/government/news/uk-economy-boosted-by-14-billion-as-longer-lorries-roll-out-on-roads

[2] https://donbur.co.uk/gb-en/products/lst-longer-semi-trailers.php

[Featured Image] Current Maximum 16.5m Articulated Lorry on Movetech UK Standard Ø17m Turntable Installed at a Dutch DC

Movetech UK vehicle access turntable keeps Marks & Spencer moving

Movetech UK (British Turntable Co Limited) have worked closely with the management teams at one of the UK’s leading retailers, Marks & Spencer, to design, manufacture and install a bespoke 12-metre diameter vehicle access turntable, sited at their prime city centre store in Chester, England.

The 44-tonne capacity turntable, which is used to rotate decoupled articulated trucks up to 16.5-metres long at a speed of 0.5rpm, has been installed in the stores service yard, and has continued to prove to be a great asset to the business.

The new turntable, is in fact a direct replacement, with the original turntable being installed in May 1990 by Movetech UK, then British Turntable Co Limited, with the new contract being agreed to replace the unit after the results of a recent inspection showed the turntable was no longer serviceable.

The stores service yard, where the turntable is located and where deliveries take place, can only be accessed from a small busy one-way street, and strict local restrictions permit vehicles to enter and exit the street in a forward direction only. Therefore, the vehicle access turntable is a vital piece of equipment to the store, and is not only key to assisting with the store’s busy delivery schedule, but also helps adhere to the local council’s stringent traffic safety rules.

After 32 years of use the turntable had most definitely surpassed its design-life requirements, exceeding expectations for many years. The new more modern and efficient unit also allowed for a new and improved, better equipped, control system, and in addition to vastly improving logistical efficiency, the new turntable and control system is compliant with modern standards and regulations.

“It’s a great feeling when a unit we designed, manufactured and installed over 30 years ago has lasted so long,” said Craig Wright, Movetech UK’s Technical Sales Director. “I wouldn’t expect anything less to be honest, but it just goes to show the quality of our products, and what we strive to offer our customers, even after years of continuous demanding use.”

“Unfortunately, it had got to a point where it was just unserviceable, and after an inspection earlier this year, the decision was made by the management teams at Marks and Spencer to completely replace the turntable with a new and improved unit, and we were more than happy to get involved.”

“We worked closely with Marks and Spencer servicing partners, Cole Mechanical Services, who both fully entrusted us to complete the job, and with a strict turnaround time, and an active store to contend with, the pressure was most certainly on to complete the project on-time and to strict deadlines.”

Craig finished by saying: “After the turntable installation was completed, and was handed back over to the store, it has continued to be one of the company’s key tools, and I am sure this one will still be operating in 30 years’ time too, just like the original one did, if not longer!”

Movetech UK worked closely with the in-store management team at Chester, M&S Head Office Project Management team, and their servicing partner Cole Mechanical Services. Specialist sub-contractors appointed and supervised by Movetech UK removed the old turntable at the site whilst a civil engineering subcontractor were appointed by M&S to undertake repairs to the turntable pit and its surround, ready for Movetech UK to install the new turntable. Whilst onsite, Movetech UK were also asked if improvements to the service yard lighting could be achieved, and as the company like to offer a full-package, when possible, the turntable experts were more than happy to appoint this task to their qualified electrical specialists, and this was also completed to a high standard the store management where more than happy with.

Dan Collier, Operations Director for Cole Mechanical Services praised Movetech UK for their hard work throughout the project, his feedback read: “I would like to thank you for all your hard work and time over the course of the project, it is truly appreciated and the result is a happy customer and a great looking new asset for them to get years of use out of!”

“I would also like to pass on my thanks to the engineers who worked on the install, for their diligence and council over the weeks on site, a big thank you to you all.”

Movetech UK will continue to work closely with Marks and Spencer and their partners Cole Mechanical Services Ltd – to service, repair and help with any queries or issues that may arise.

For more information on this particular project, product or if you have any questions, don’t hesitate to contact us, telephone; 01204 525626, or email; info@movetechuk.com. Alternatively visit www.movetechuk.com.

An in-depth look at Movetech UK’s new innovative Construction Site Turntable

An 8m diameter, 32 tonne capacity, vehicle access turntable, designed and manufactured by Movetech UK has recently been unveiled, and is undoubtedly going to revolutionise the construction site industry.

This innovation has been in development for several years with Movetech UK’s technical team focused on designing a solution for construction sites where space is limited and handling the hundreds of vehicles required to keep the site running smoothly is both a logistical and a safety challenge.

Craig Wright, Movetech UK’s Technical Sales Director explains more: “The concept derived off the back of many enquiries over the last few years with a high-demand for an industrial type of turntable for temporary use, but with a few key differences to our typical truck turntable solution offerings.”

The same questions and requirements where being asked repeatedly, all of which we could happily help with by implementing a typical fully circular and flush-fitting turntable which usually incurs a 5-to-6-month lead time from consultation to completion. But with many enquiries demanding tight timeframes and temporary use, we were unable to fully offer an accessible off-the-shelf ‘we need it next week for a few months’ type solution.”

“I sensed we urgently needed to come up with a solution, we are the market leaders when it comes to truck turntables, we are the experts,” added Craig. “So, we 100% needed to design a turntable that was strong, rigid and could be installed easily, in very limited space, and was readily available on a long or short-term rental basis, or to even purchase.”

We completely understand construction site turnaround times are fast paced to keep up with the ever-flowing demand of on-site deliveries, and by installing a construction site turntable we can also significantly reduce dangerous reversing manoeuvres in what can already be a hazardous environment, helping to improve upon already vigorous health and safety measures.”

Therefore, we designed and manufactured a concept turntable, thoroughly tested it, and now we have a new vehicle turntable to add to our ever-growing portfolio of movement solutions – it ticks all the boxes, and can be delivered to a site, as quickly as tomorrow if required. Problem solved!”

The concept becoming a reality also somewhat hails from the success of a project the company was recently involved in too. A large-scale development at the core of London’s King’s Cross district – positioned adjacent to the extremely busy King’s Cross station, which proved to be very problematic for the sites management team.

Due to the location, and the long and narrow architectural footprint of the construction area, it left very little room for deliveries to and from the site, therefore a traffic management plan had to be devised to find a suitable solution to comply with regulations, allowing the delivery trucks to enter and exit the construction site safely, in a forward gear.

When the development contractors approached Movetech UK to potentially install an on-site truck turntable, they suggested the turntable should be installed in a pit, however after working closely with their project team, Movetech UK eventually came up with an above-floor option. This option removed the need for costly on-site preparations and meant that when the turntable was eventually removed, there were no pit to fill – and albeit not the process a turntable would usually be installed, it worked, and it was successful.

Movetech UK have manufactured and installed many Ø15m units for HGVs and trucks over the years, but this was the first temporary unit for a construction site they are aware of in the UK, and undoubtedly supported the idea and concept process of the new construction site turntable.

The new construction site turntable allows the vehicle to drive on to the turntable platform using the robust galvanised steel ramps with a maximum turntable capacity of up to 32 tonnes. It is suitable for up to 4-axle rigid vehicles such as tippers and muck-aways, with a maximum wheelbase of 6.5m and 2.5m width across tyres. The unit also offers galvanised steel guide bars, mounted along the edges of the turntable and ramps, permitting additional safety, and control.

Once parked, the vehicle is rotated at approximately 0.4rpm in the smallest space possible with momentary buttons on the remote operator station. This allows a 180-degree turn to be completed in approximately 75 seconds.

The turntable platform rotates 180-degrees to align with the ramps, to allow the vehicle to drive off in a forward gear. At only 3kW to rotate 32 tonnes and require a standard 32amp 415v supply, the turntable is relatively low power.

The length of the turntable platform is 8m with a width of 2.84m and a heigh of 0.9m. The total space required including the ramps is approximately 15x10m – with the design allowing the turntable to be quite easily moved to a new position in around 1-2 days.

Contact Us

If you would like more information or to take advantage of what will no doubt become a very popular unit, get in touch with Movetech UK’s sales and technical teams today, and they will be more than happy to help with any questions you may have. Tel: +44 (0)1204 525626, Email: info@movetechuk.com.

– – –

The video clips and images included in this article were taken at a secure location, for testing and marketing purposes, by Movetech UK – British Turntable Co Limited. With a special thanks to Armstrongs Group (Bolton).

Movetech UK designs, manufactures and installs its largest ever vehicle access turntable in mainland Europe

Movetech UK have worked closely with the management team at one of the world’s largest retail companies to design, manufacture and install a bespoke 17m diameter vehicle access turntable, sited at one of their large European stores in the Netherlands.

The project started with the retailer’s management team putting a plan together to extend their existing warehouse space, but with the store being surrounded by a protected nature reserve, the only available space to extend the store would be to construct into the current delivery yard area.

The proposed plan drastically reduced the space in the service yard; therefore, a turntable was the obvious solution to help manage the day-to-day deliveries to and from the store. By designing and installing a new bespoke 17m diameter vehicle access turntable, it would allow for the proposed construction of the additional footprint to be added to the warehouse, additionally allowing the delivery vehicles to continue to make their scheduled deliveries, both safely and efficiently.

“The retail stores primary objective was to extend their warehouse capacity” said Craig Wright, Movetech UK’s Technical Sales Director. “But knowing this would drastically reduce the amount of space the delivery vehicles would have to turn around in, it just wouldn’t have been a safe option to allow the vehicles to manoeuvre in such a small area, so a vehicle access turntable was undoubtedly the perfect solution.”

Craig then went on to say: “To make the delivery yard work efficiently and safely within the reduced delivery area, installing a turntable would certainly achieve this, and would allow the store to push forward with their plans to extend their warehouse capacity.

“The 17m diameter, 50-tonne capacity revolve, is the first, and largest, vehicle access turntable we have ever had the pleasure in designing, manufacturing and installing in mainland Europe, and from the consultancy phase, right up to the installation and handover, it has been an exceptionally enjoyable project, particularly when you’ve successfully helped turn someone’s problem into a solution.

“From start to finish, the whole process has taken 13 months, and we are more than happy with the end result. We are extremely honoured to have been given the opportunity to consult and offer a successful solution to the access problems the stores management team encountered.

“We will continue to support the company, by training the staff on how to use the turntable, in addition to servicing the turntable to make sure it continues to provide the high standards we expect from every one of the products we produce.”

Ian West, Movetech UK’s Technical Engineer added “I’ve been involved on this project from the very beginning, and the detail put into the design has allowed the installation of the turntable within the delivery yard to occupy as little land as possible, leaving more space for the store’s additional warehouse capacity, which was the stores main goal in this particular project.

“The added benefit of the stores delivery vehicles being able to drive straight into and out of the delivery area, without the need to make complete manoeuvres to turn the vehicles around, has also vastly improved the overall safety of the yard, as well as increasing efficiency by allowing deliveries to be completed in a much faster time scale.”

Ian then finished by saying “For this type of turntable, 44 tonne capacity is usually all that is needed in the UK and most of Europe, so being given the opportunity to be able to expand our expertise beyond this, as regulations in the Netherlands are slightly different, have been a great way of demonstrating whatever problem we are faced with, we will always produce a solution.”

Movetech UK vehicle access turntables provide effective access solutions, from improving car parking provision in city centre office blocks, to enabling delivery trucks access to sites that would not otherwise be accessible.

Additional benefits of a vehicle access turntable include meeting local planning requirements where a vehicle is required to enter and exit in a forward gear, assisting vehicles manoeuvring in a restricted area creating a safer working environment, freeing up storage space for more profitable use, as well as helping lower work environment pollution by reducing vehicle engine emissions, and improving logistics by reducing delivery turn round times.

Construction site benefits from a 15m diameter Movetech UK Vehicle Access Turntable

A 15m diameter, 44 tonne capacity, vehicle access turntable installed by Movetech UK at the location of a new multi-million-pound construction in London, is not only speeding up delivery turnaround times for the contractor, but is also proving to offer many other economic and operational benefits.

The construction company’s development of the new building, is sited at the core of London’s King’s Cross district and is positioned right next to the extremely busy King’s Cross station, which has proven to be very problematic when it comes to the delivery of construction materials.

Due to the location, and the long and narrow architectural footprint of the construction area, it left very little room for deliveries to and from the site, therefore a traffic management plan had to be devised to find a suitable solution to comply with regulations, allowing the delivery trucks to enter and exit the construction site safely, in a forward gear.

As the surrounding area also sees a footfall of thousands upon thousands of pedestrians every day, public safety was also a major factor the company had to consider.

Movetech UK worked closely with the project’s management teams, and with the company knowing the small amount of space the delivery yard had to manoeuvre and operate in, a vehicle access turntable was undoubtedly the obvious solution to help manage the day-to-day transportation of materials to and from the construction site.

A vehicle access turntable would typically be installed as a permanent solution in areas such as delivery yards, and would generally be required to be installed inside a recessed turntable pit, so that the turntable platform would sit perfectly level with the current yard surface – but with this project, it had to be slightly different, because the turntable was required to be installed above ground level.

Craig Wright, Movetech UK’s Technical Sales Director, explained further: “When we were originally approached by the contactors, we suggested the turntable should be installed in a pit, however after working closely with their project team, we eventually came up with the above-floor option with a lightweight pedestrian walkway around the turntable. This removed the need for costly on-site preparations, and meant that when the turntable is eventually removed there will be no pit to fill.

“The location of the turntable is directly adjacent to the eventual footprint of the development so complex manoeuvres were just not an option for the client. The turntable allows the delivery drivers to complete their deliveries by entering the construction site in a forward gear, from a busy main road, and drive up a pre-made narrow through road, where they would then park on the turntable, the vehicle would then rotate, allowing the drivers to complete their deliveries, and then exit safely, again – in a forward gear.”

Craig continued: “We have manufactured and installed many Ø15m units for HGVs over the years, but this is the first temporary unit for a construction site we are aware of in the UK.”

“In addition to everything else, construction site traffic management is a critical area of Health and Safety, with reversing vehicles posing a significant risk to personnel on construction sites. By removing the necessity for vehicles to reverse, whilst simultaneously reducing the space required to turn around, the turntable has made the site safer and more efficient. As sites become more and more restrictive, turntables offer an elegant but robust solution.”

Movetech UK will continue to help and support the contracting company, by offering on-hand help and advice, in addition to servicing the turntable throughout the construction process, to make sure it continues to provide the high standards they expect from every one of the products they produce.

The advantages of using a vehicle turntable vary from one application to the next, however where they add value in most cases is to reduce turning space and potentially dangerous reversing manoeuvres, subsequently improving the health and safety within the restricted area. End users can eliminate large turning circles and complex manoeuvres, not only saving fuel and tyre wear, but more importantly reducing emissions to zero at the point of use, further improving the working environment for operatives in the area.

Movetech UK vehicle access turntables provide effective access solutions, from improving car parking provision in city centre office blocks, to enabling delivery trucks access to sites that would not otherwise be accessible.

With 60 years’ experience behind them, Movetech UK offer excellent customer service and superb product quality – their products often outlive their design life, and many units are still working after tens of years in service. With a first-class rental team to match, they supply a wide range of turntables and movements to the biggest names in the industry.

Second British Turntable HGV Access Turntable for Waitrose

British Turntable has supplied a second 15 metre diameter HGV access turntable to Waitrose, creating an efficient loading and unloading operation at the company’s new store in Wallingford, Oxfordshire. The contract follows the success of the unit British Turntable had previously installed in the underground loading area at the Surbiton store in Surrey.

Installation of the turntable has allowed the service yard to occupy as little land as possible, leaving more space for the store’s sales area; additionally, vehicles can drive straight into and out of the service area, a safer procedure for the village, whose roads are very narrow and busy.

The turntable fills the service yard and is capable of taking an articulated truck up to 16.5m long and with 40 tonnes capacity. On entering the yard from the main road, the truck drives straight onto the turntable and is then rotated approximately 90 degrees to line it up with the unloading dock; after unloading it can be rotated a further 90 degrees to allow it to drive straight out again.

As the service area is so restricted the turntable has been designed to allow cages to be stored on an area of the turntable not required by the truck and also for a transit-sized van, used by the store for home deliveries, to be parked on the turntable without preventing an articulated truck from using it. The cages and van simply rotate with the turntable.

A safety light beam has been installed to protect a static construction close to the turntable; if the beam is broken this will stop the turntable from rotating further.

The Waitrose turntable has been adapted from one of British Turntable’s standard vehicle revolve designs and is typical of the many vehicle revolves which British Turntable has manufactured and installed in government buildings, major high street stores and other commercial establishments throughout the world.

Standard features of the HGV access revolve design include: a fixed speed rotation of 0.5rpm, which allows vehicles to be moved into the ideal position in only 60 seconds; yellow markers to make positioning of the vehicle on the turntable easier; and a vandal-proof, security key protected control box to aid the manoeuvring process. The turntable components are generally located in a pit that has provision for water drainage.

ASDA Benefits from British Turntable Access Revolve

A 15 metre diameter HGV access revolve installed by British Turntable at the new Asda store in Bearsden, Glasgow, is not only speeding up delivery turnaround times but is also proving to offer other economic and operational benefits.

The 44 tonne capacity revolve, which is capable of carrying an articulated truck up to 16.5m long, has been sited in a covered service yard, which is accessed from a busy main street. Vehicles must enter and exit this street in a forwards direction, and a solution therefore had to be found which would allow delivery vehicles to be turned round in the restricted loading area.

A turntable was the obvious choice with British Turntable chosen as the supplier.

Asda had been looking at installing turntables for a number of years and prior to the Bearsden installation visited Marks & Spencer and Waitrose stores where British Turntable access revolves had previously been installed. They were impressed with the simplicity of the turntable operation at these sites.

Asda’s primary objective was to make the yard work better, and the installation of the turntable at Bearsden has achieved this. It has been instrumental in improving the layout and product flow of the back-of-house at the new store, and the cost of the turntable has been partially offset by the reduction in excavation costs in the rear yard.

After only a couple of training sessions the store team and delivery drivers have become used to the turntable, such that the docking operation is now quick and straightforward.

British Turntable agreed a generic turntable specification with Asda for the Bearsden store, and this was then adapted in consultation with the architect to meet the site’s specific needs. As part of this a simple red/green traffic light arrangement has been provided by British Turntable to inform drivers waiting at the entry door if the turntable is clear of traffic and ready to accept their truck.

Standard features of British Turntable’s generic turntable design include: a fixed speed rotation of 0.5rpm, which allows vehicles to be moved into the ideal position in only 60 seconds; yellow markers to make positioning of the vehicle on the turntable easier; and a vandal-proof, security key protected control box to aid the manoeuvring process. The turntable components are generally located in a pit that has provision for water drainage.

Staff training is also included, as is stand-by provision on store opening, an emergency rotation facility and maintenance.

Case Studies

| Client | Case Study |

|---|---|

| Marks & Spencer, Chester, UK | View / download (PDF) |

| Waitrose Supermarket, Surbiton, Surrey, UK | View / download (PDF) |

| Kyle Stewart Ltd, Installed at 33 Old Broad Street, Central London, UK | View / download (PDF) |

| Interior Plc, Installed at Fleetbank House, Salisbury Square, London, EC4, UK | View / download (PDF) |

| HBG Construction for M&S Store, Fenchurch Street, London, UK | View / download (PDF) |